iGOLDENOF

Shandong iGolden Furniture Co., Ltd. was established in 2012 and is located in Jinan City, Shandong Province. It is a professional supplier of hospital furniture, bank furniture and various customized office furniture. It is a large-scale manufacturing enterprise integrating design, development, production and sales. For more than ten years, iGOLDENOF has been highly recognized and appraised by customers from all walks of life for its open-mindedness, solidarity, mutual assistance, hardworking, pragmatic and humble entrepreneurial spirit and the pursuit of excellence.

After the furniture R&D and design team’s continuous research and development, upgrading and improvement of products, iGOLDENOF has become the designated supplier of many hospitals, nursing homes, rehabilitation centers and other medical institutions, banks, financial centers and other financial outlets.

Market policy-grow up with partners

Perfect agency policy and market protection policy, adhere to customer first service. We always hope to meet the needs of customers and product users in our service process. We are committed to growing together with our customers and partners.

Environmental protection advantage

Our company has a complete environmental protection production system. From the entry of raw and auxiliary materials to the delivery of finished products, strict screening is carried out to ensure that furniture materials meet environmental protection requirements. First, after the raw and auxiliary materials enter the site, they will be randomly inspected in batches and sent to a third-party testing agency for testing. After the inspections are passed, they will be approved for production. The quality is strictly controlled during the production process.

Quality control-strict quality control system

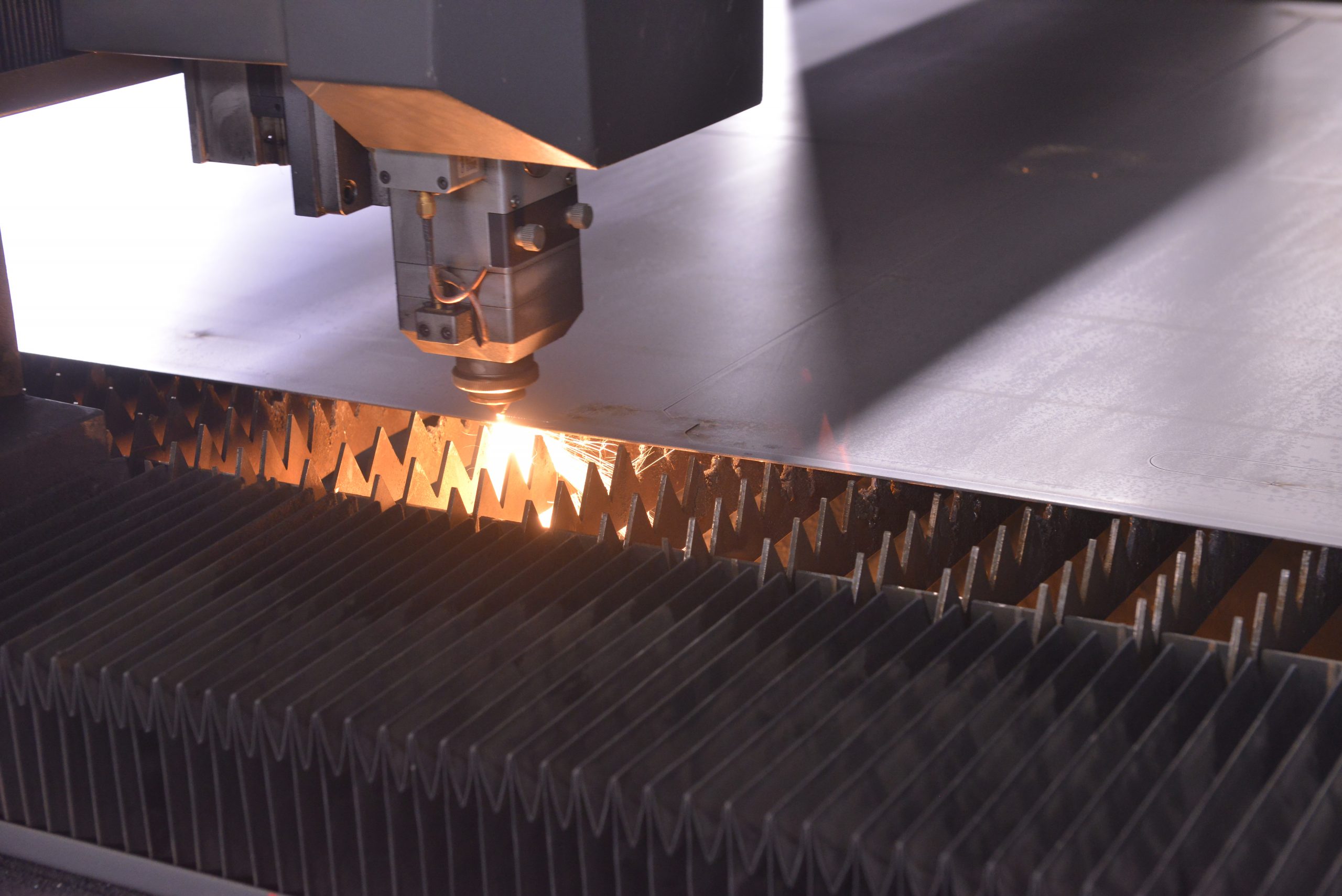

Each piece of furniture needs to go through more than eight production processes from order to delivery, using advanced production equipment, such as: CNC machine tools, row drilling machines, edge banding machines, etc. After the order is signed, the production workshop will actively cooperate with this project to formulate an orderly production plan, arrangements to ensure efficient completion of the order supply during the supply period.

What Our Clients Say?

Choose iGOLDENOF, the reputable supplier of business furniture, we will cooperate on the basis of complete trust and comfort.

We understand that every customer is valuable and will cherish every opportunity for cooperation!