Steel composite wall panel as a public space (such as bank, communications center, service center, office buildings, hospitals, etc.) a kind of interior wall material, the product of scraping resistance, fire prevention, environmental protection, moistureproof, prefabricated piping installation, go line, antibacterial and no radiation performance is more and more get the welcome of designers and…

Category Archives: News

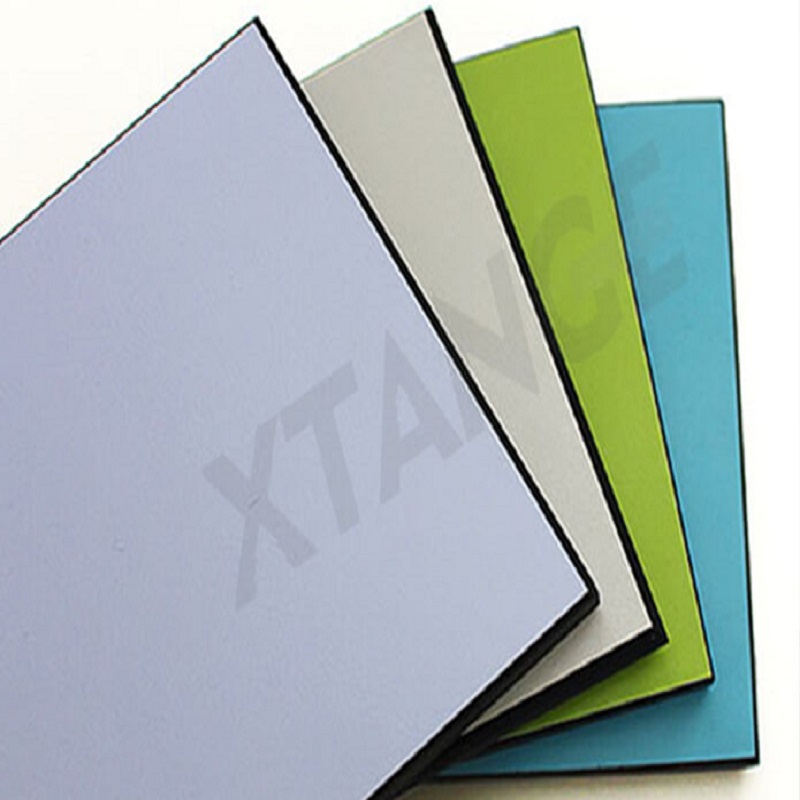

1: observe the thickness of the substrate and the thickness of the film Color steel plate is composed of a substrate and a colored peritoneum or coating. We first have to consider the thickness of the substrate and peritoneum coating, the better color plate substrate is 0.02~0.05mm, film or coating thickness is often only 0.15mm…

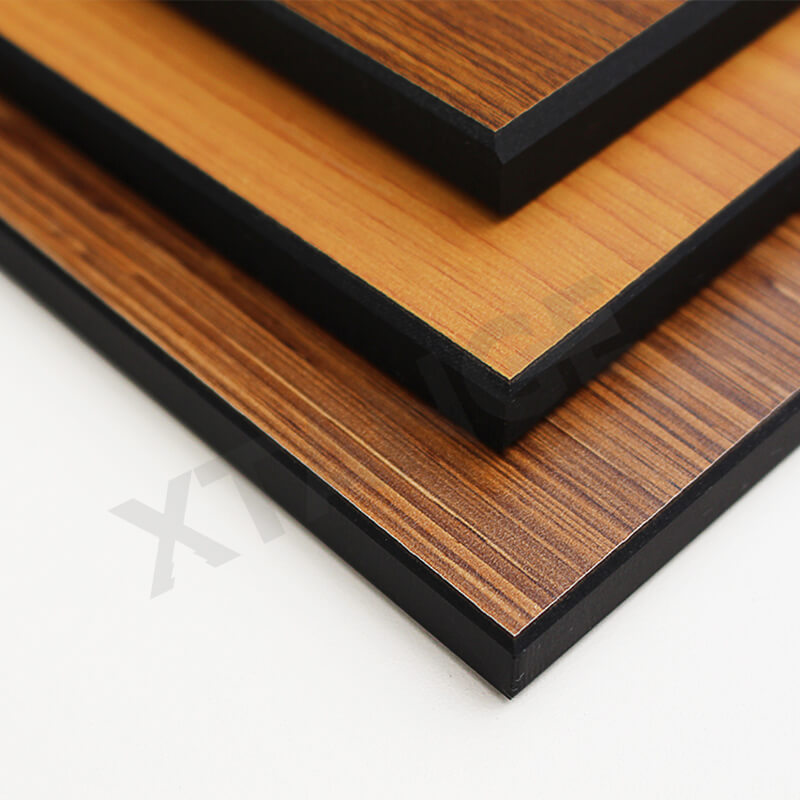

Color steel sandwich panel is composed of two layers of color coating steel plate as the panel, with thermal insulation materials such as polystyrene, polyurethane, phenolic foam, rock wool as the core material, in a special automatic production line, the continuous forming process will be the core material and panel composite into a whole building…

The process of manufacturing aluminum plate is introduced 1, aluminum and aluminum alloy strip in hot rolling state, annealing state, various levels of soft and various heat treatment state supply. 2. Preparation before hot rolling mainly includes ingot quality inspection, soaking heat, sawing, milling, aluminum wrapping and heating. 3, semi-continuous casting cooling speed is very…

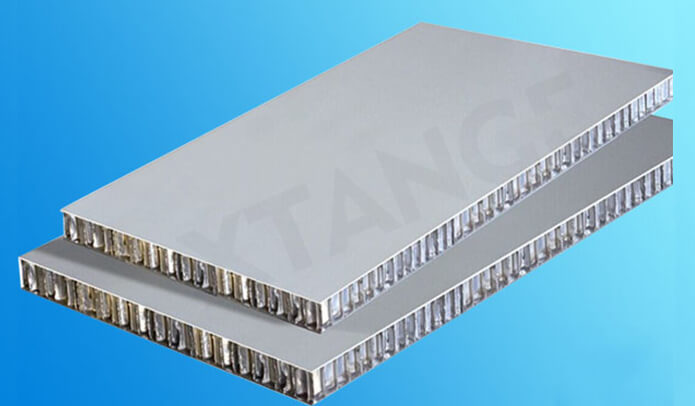

First, there are problems in the selection of stone aluminum honeycomb composite board Whether the aluminum honeycomb type of stone aluminum honeycomb composite board is correct is an important factor to determine whether the stone aluminum honeycomb composite board is deformed. When the author just contacted the stone aluminum honeycomb composite panel, it was not…

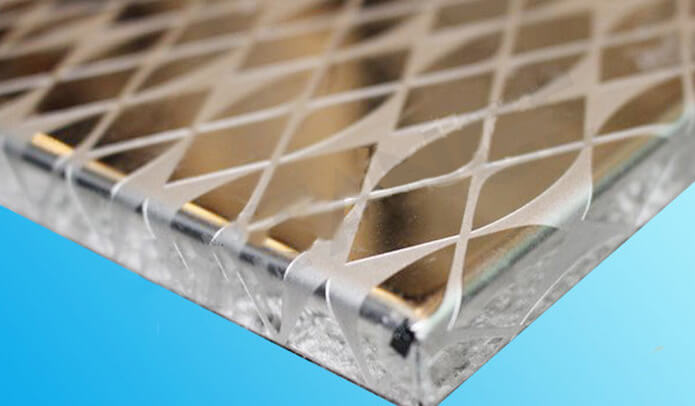

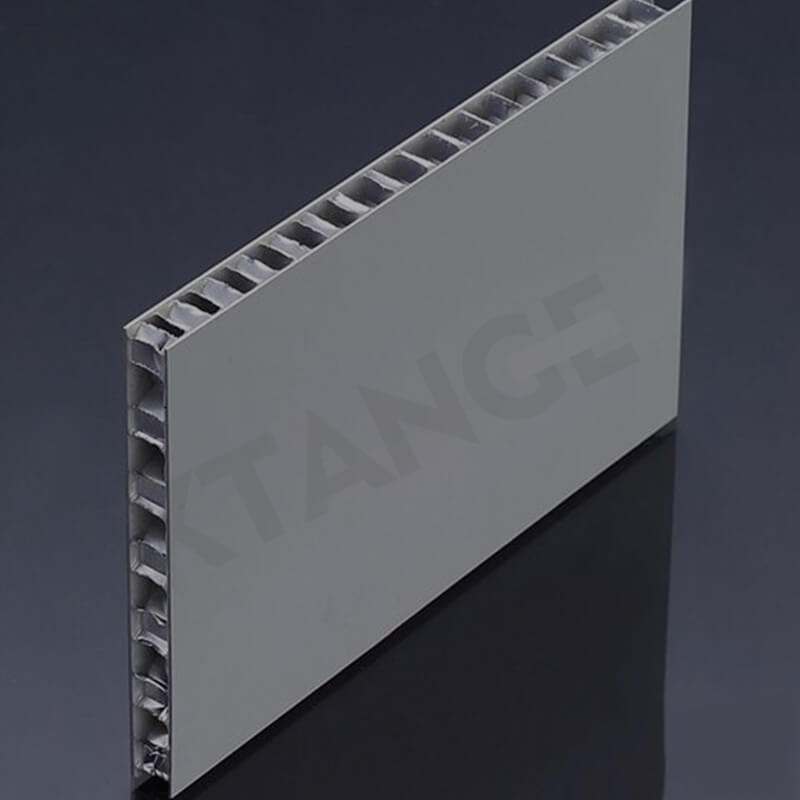

(1) Inspection scope: panel, bottom plate: check the size of the board (the workshop should pay attention to cutting in strict accordance with the standard size when cutting), thickness, weight, flatness, cleanliness. Aluminum honeycomb: Check the height of the honeycomb, as well as the weight. (2) Inspection process: when the raw materials are put into…

Composite Process of Aluminum Honeycomb Panel (1) Spread out the aluminum honeycomb in advance, and cold pressing leveling: duration: more than 4 hours, pressure :10-25 tons. The preparation of glue: the mixing ratio of the main agent and curing agent is: the main agent 4, curing agent 1. (3) Lift the press to an appropriate…

Honeycomb Panel Production Process and Inspection Standards (1) Regularly check the machine, blade, die, vacuum cleaner, high-pressure air pump and other operating equipment. (2) Place the honeycomb panel formed by cold pressing on the cutting table, with the panel facing up, and press it by moulding. ③ The finished size of honeycomb plate cutting is…

1, look at the raw materials and appearance processing. High-end machine room wallboard manufacturers naturally strictly control the production of products, so for identifying the quality of the room wallboard can be viewed by the selection of raw materials. 2. Look at the technical ability of the manufacturer. Room wall panel manufacturers are welcome by…

There are many toilet clapboard materials on the market now, common anti-times special board, anti-times special honeycomb board, PVC composite board and so on. So, can metal honeycomb panel do toilet partition? IGOLDENOF has proved that metal honeycomb panels can be used as toilet partitions through repeated research and development. Its superior performance, more suitable…