Aluminum corrugated plate is also called corrugated aluminum plate, pressed aluminum plate, aluminum tile, etc. It is suitable for industrial production and industrial construction, warehouse, special engineering construction, flat roof, wall and interior and exterior decoration of large span light steel structure house. With light, high strength, colorful colors, engineering construction time-saving, seismic grade, waterproof and rainproof, maintenance free and other characteristics, has been widely used and promoted.

1, aluminum tile (corrugated aluminum plate, corrugated aluminum plate, pressure aluminum plate) light quality, the relative density is only one-third of the stainless steel plate. Similarly thin thick carry forward to the price of every square metre, the price of stainless steel plate and aluminum profile differ as good.

2, corrugated aluminum plate (aluminum tile, corrugated aluminum plate, pressure aluminum plate) is easy to produce and process forming, engineering construction time and labor saving, large engineering construction compressive strength.

3, wavy aluminum plate (aluminum tile, corrugated aluminum plate, pressure aluminum plate) beautiful and generous, atmospheric, atmospheric, with aluminum skin to do thermal insulation decoration design, bright space sense is very good, wrapped up the pipeline after the overall vision is good.

4, profiled steel plate (. Aluminum tile corrugated aluminum plate, corrugated aluminum plate) long application period, aluminum corrosion resistance is good, storage life is about 15 years.

5, aluminum tile (corrugated aluminum plate, pressure aluminum plate) comprehensive use of high use value, tin will be corroded after two years of use, basically no comprehensive use value, but aluminum coil (aluminum skin) with its corrosion resistance, after the acquisition of the use value of the melting furnace is much higher, less comprehensive use of about 80%.

6, aluminum tile (corrugated aluminum plate, pressure aluminum plate) is widely used in chemical plants, power plants, pharmaceutical plants, agricultural pharmaceutical plants these waterproof engineering.

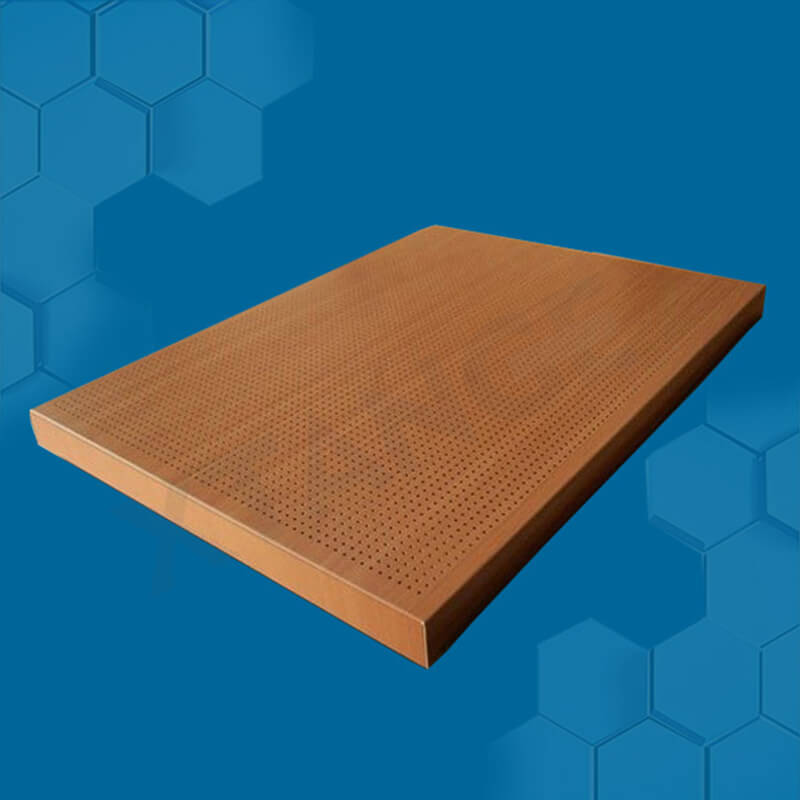

Aluminum honeycomb panel is suitable for industrial building, vehicle and ship decoration design. Airline, aerospace raw materials in industrial construction applications. All the production process is carried out in the intelligent processing plant, and the pressure synthesis technology is selected. Because of the high thermal conductivity between the aluminum skin and the honeycomb, the heat expansion and cold contraction of the inner and outer aluminum skin are at the same stage; Honeycomb aluminum skin with small round holes, so that the steam body can freely flow; Draggable installation buckle system software is not easy to cause structural deformation when hot expansion and cold contraction. The control panel key uses high-quality 3003H24 aluminum alloy aluminum plate or 5052AH14 high manganese aluminum alloy plate as the plate, the control panel thickness of 0.8~1.5mm fluorocarbon spraying roller coating plate or resistance to complex color light spray paint, resistance to complex color light spray paint in scratch resistance, acid rain erosion fading, self-washing performance is stronger than PVDF, The thickness of the base plate is 0.6~1.0mm, and the total thickness is 25mm.