The main performance of aluminum honeycomb panel: decorative performance

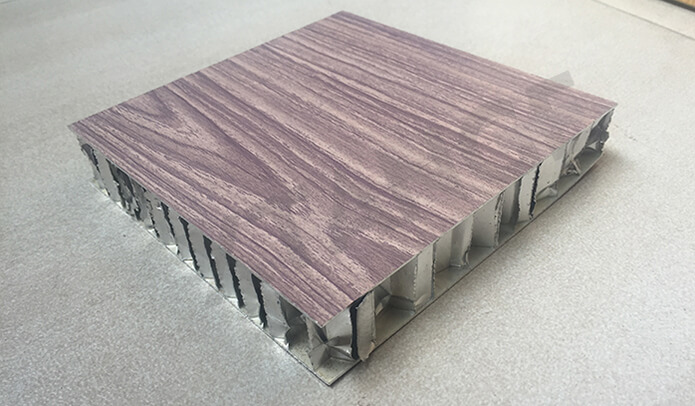

The surface coating of aluminum honeycomb panel is fluorocarbon paint, polyester powder spraying, acrylic paint, fluorocarbon or polyester roll coating decoration. Because aluminum honeycomb plate is equivalent to countless I-beam structure, it is endowed with large rigid bending strength and small bending deformation. Honeycomb panel has high flatness, which is much better than single aluminum plate and aluminum-plastic plate, and can produce larger size plate (1.5m×10m), which meets the design concept of designers. In addition, because aluminum honeycomb panel can realize the processing of “L” shape, “U” shape, single arc shape and other shapes, it can fully meet the requirements of architectural decoration on the special-shaped.

The main performance of aluminum honeycomb panel two: mechanical properties

Aluminum panel, aluminum honeycomb core, adhesive is an important factor to determine mechanical properties of the aluminum honeycomb panel, different specifications, materials, raw materials processing and manufacturing of aluminum honeycomb panel there are big differences in the mechanical properties, materials must be chosen according to its use in the building site, force calculation in detail, so as to determine the material specification.

The main performance of aluminum honeycomb panel three: sound insulation, thermal insulation performance

Because of its unique structure, aluminum honeycomb panel has certain performance of sound insulation and heat insulation.

The main performance of aluminum honeycomb panel four: sound absorption performance

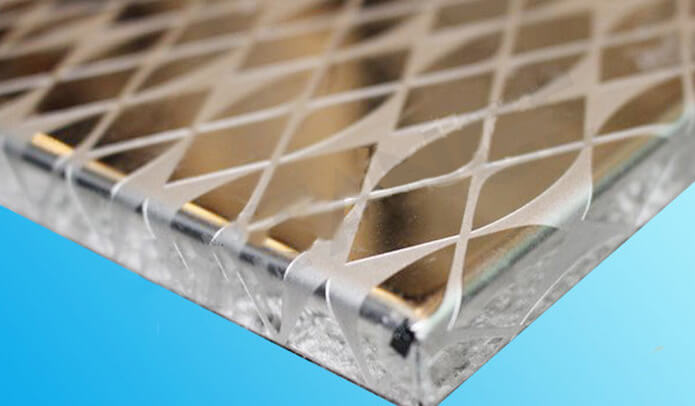

At present, as a requirement of acoustic performance of the occasion, such as hall, hall, hall, field decoration sound-absorbing board, green landscape building materials aluminum honeycomb sound-absorbing board and other sound-absorbing materials such as sound-absorbing paper, glass fiber cotton function combination, play their respective advantages, can play a better sound-absorbing effect. From perforated plate, aluminum honeycomb and sound-absorbing paper combination of acoustic board affected by the sound absorption characteristics of three different materials, each material has its unique variable sound absorption effect, change the way of combination and the density of material itself, height and other parameters can obtain different degree, the combination of dozens of different performance effect, can reach the effect of different frequencies of sound absorption. In the actual use, the need according to indoor environment and sound requirements to determine the acoustic absorption coefficient of different frequencies, in order to choose the combination of different materials, and cooperate with the installation in order to achieve different sound effects.

Honeycomb sound-absorbing board can be processed according to the design of different perforation rate of the finished product to meet the design of sound absorption requirements, but also according to the design of the appearance of manufacturing into a variety of curved surfaces and special-shaped. Because of its enough rigidity, the honeycomb plate has a small vibration in the sound field, which is only about 1/6 of the single plate, so it can greatly reduce the noise interference caused by resonance.

Sound absorption coefficient of aluminum honeycomb perforated sound-absorbing board

Frequency /HZ 100 125 160 200 250 315 400 500 630 800

Sound absorption coefficient α 0.52 0.67 0.46 0.98 0.98 00.95 0.99 1.01 0.98 1.00

Frequency /HZ 1000 1250 1600 2000 2500 3150 4000 5000 ā NRC

Sound absorption coefficient α 1.02 1.04 1.06 1.02 0.99 1.04 0.95 0.94 0.91 1.00

Note: Perforation rate 16%, back space 400mm

The main performance of aluminum honeycomb panel five: environmental performance

The aluminum honeycomb panel does not emit harmful gases in the process of production and use. And because it is all aluminum products, dirt resistant and easy to clean, can be directly recycled, waste products do not pollute the environment; It is a reusable green material. Production of honeycomb sound-absorbing board generally use thermosetting modified epoxy structure adhesive bonding, adhesive curing form polymer structure, long-term use temperature of -60℃ ~ +80℃, under normal use temperature, it does not have any low molecular volatile matter dispersed, with good toughness, heat resistance outstanding, good durability characteristics.

Aluminum honeycomb panel set decoration and architectural acoustics for a suit, can meet the design requirements of architectural decoration and architectural acoustics, has high strength, good rigidity, light quality, super smooth, colour and lustre is uniform, sound insulation, heat insulation, thermal insulation, moistureproof, fire prevention, resistance to wind pressure, seismic, weather resistance, long service life and processing advantages of convenient installation, color optional sex is wide, Its performance and price ratio exceeds that of traditional aluminum-plastic composite board and aluminum veneer, and it can be processed into large-size decorative board with flat surface, which expands the space of architectural designers and has infinite potential in the future market of architectural interior decoration.