Stone aluminum honeycomb panel indoor ceiling construction technology: keel installation

(1) The ceiling keel and boom are made of L50×5 galvanized Angle steel, the thickness of galvanized layer is ≥75μm. Process and install according to keel structure drawing, adjust civil construction error according to lofting datum line and datum surface.

(2) Determine the position and direction of the main and auxiliary keels according to the ceiling layout drawing of each area. The distance between the hanger rods is 900 ~ 1 200mm, and the distance between the main and auxiliary keels is determined according to the size of the ceiling plate. Additional keels should be installed where access is required.

(3) The distance between the boom and the end of the main keel shall not exceed 300mm, otherwise, the boom shall be added to avoid the main keel falling. When the boom meets the equipment, the lifting point shall be adjusted to ensure the quality of the ceiling.

(4) The suspender and the steel structure beam or reserved steel plate embedded parts and between the keel and the keel, keel and the suspender are connected by welding, welding first spot welding, then full welding, welding foot height of 4 ~ 6mm, anti-corrosion treatment after full welding.

(5) When the boom needs to be lengthened, it must be welded firmly with uniform and full welds; When boom length > 1. At 5m, set the back support. Stone Institute (wechat id: stone5A)

(6) In order to minimize the influence of the sinking deflection of the steel keel on the flatness of the decorative surface of the suspended ceiling, the middle part of the keel should be arched, and the arched height should not be less than 1/200 of the short span of the room.

(7), condole top after the installation of the keel, dragging steel keel bottom chord line inspection acceptance, the steel keel of local elevation error is too large, which is set in the middle of steel keel shores, by using the method of welding heat, the deformation of steel keel slightly, leveling to error within 2 mm, in order to meet the requirements of surface roughness at the base.

Stone aluminum honeycomb panel indoor ceiling construction technology two: hanging installation

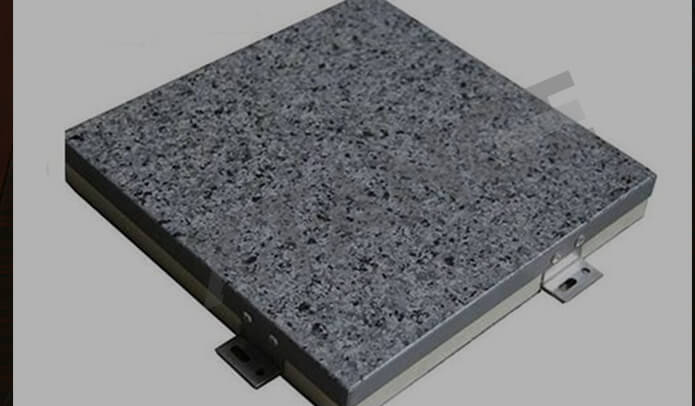

(1) after the stone aluminum honeycomb board is transported to the site, first review the processing size of each board, mainly review whether the plate size and thickness size deviation is within the allowed range, if there is a deviation affecting the installation should be returned to the factory for re-processing.

(2) The pendant is stainless steel pendant, which is divided into “Z” shape and “one” shape. The “Z” shape and “one” shape of the adjacent plate shall be stagger arranged. Pendant thickness ≥4mm, width 40mm, pendant is arranged on the back of the long side of the plate, the number of pendant is determined according to the length of the plate, when the length of the plate ≤600mm, the number of pendant is 2; When the length of the plate is between 600 mm and 1 000mm, the number of pendants is 3. When the length of the plate is between 1 000 ~ 1 500mm, the number of pendants is 4. When the length of the board is between 1 500 mm and 2 000mm, the number of pendants is 5.

(3) Drill holes on the back of the stone aluminum honeycomb plate according to the installation position of the pendant, and the hole position should be consistent with the hole position on the pendant.

(4) Inject epoxy resin glue into the hole and fix stainless steel pendant with riveting gun. There are not less than 2 rivets on each pendant, and the diameter of rivets is 4mm. The contact surface between honeycomb aluminum plate and stainless steel pendant is isolated by insulating sheet to prevent electrochemical corrosion.

Stone aluminum honeycomb panel indoor ceiling construction technology three: pipeline equipment installation

(1) The installation of pipeline equipment shall be balanced comprehensively, rationally arranged according to the construction quality acceptance specifications, geometrical dimensions of pipelines, space in the ceiling and function of use, and comprehensively balanced the positions of professional pipelines to minimize the crossing of pipelines and meet the clearance requirements of the ceiling.

(2) Before installation of decorative panels, the installation of pipelines and equipment in the ceiling must be completed, and qualified by inspection and pressure test.

Stone aluminum honeycomb panel indoor ceiling construction technology four: ceiling board installation

(1) According to the layout diagram of each space, the stone aluminum honeycomb panels equipped with stainless steel hangers shall be pre-arranged on the ground of the site according to the number, and numbered one by one according to the requirements of the lofting diagram number.

(2) When installing stone aluminum honeycomb panels, install them according to the layout diagram to avoid mistakes and ensure smooth texture and uniform color difference.

(3) Under the dragon skeleton that has been installed and accepted by concealed works, separate blocks shall be hung according to the specifications of the panel. Install a row of cover panels starting from one side of the ceiling. With this as the benchmark, install the plates one by one backward according to the layout diagram.

(4) plate seam spacing 5mm. Self-tapping bolts are used to fix the “Z” shaped pendant and the suspended ceiling keel. At least 2 self-tapping bolts are fixed on each pendant and the suspended ceiling keel. The “ONE” shaped pendant is mounted on the completed suspended ceiling plate, and the lap length is ≥40mm5)

(5) Check the line, including the horizontal and horizontal positions and elevation, and tighten the tapping bolt to fix the plate after ensuring no error. Make sure the plate is straight, the seam width is consistent, and the seam has no visual height difference.

(6) When the ceiling board is installed, other materials shall not be placed on the stone honeycomb aluminum composite board to prevent the deformation of the board surface under pressure.

(7), the ceiling should be considered comprehensively on the panel of lamps and lanterns, smoke sensor, sprinkler head, air outlet grate and other equipment, so that the position is reasonable, beautiful, and the decoration of the panel should be anastomoses, tight.

Stone aluminum honeycomb plate indoor ceiling construction technology five: plate seam glue

(1) Caulking and gluing can be carried out after the installation of stone honeycomb aluminum composite panel is completed in a section. Before gluing, clean up the debris around the plate seam and clean up the dust in the stone seam with a steel wire brush.

(2) Before gluing, special protective tape should be glued on both sides of the seam to prevent pollution of stone. Fill the gap with foam rod, and the caulking depth should be suitable for the thickness of the glue seam.

(3), in the same direction with a glue gun sealant evenly injected into the seam, and immediately with a scraper scraping, then remove the tape, the thickness of the weatherproof sealant should be 6 ~ 8mm, the rubber surface is smooth and beautiful, without wrinkles.

(4) weather resistant sealant must be tested with stone composite board to prevent pollution of stone.

Key points of quality control of stone aluminum honeycomb panel

(1) Varieties, specifications and models of stone aluminum honeycomb panels should meet the design requirements, and there must be factory certificate, quality guarantee and performance inspection report.

(2) The stone aluminum honeycomb panel should have no cracking, no positive Angle and burst edge, and the allowable deviation of size and edge grinding treatment should meet the standard.

(3) The performance test indexes of stone aluminum honeycomb panels shall comply with relevant standards.

(4) The grade and state, chemical composition, mechanical properties and allowable size deviation of the steel used for the suspended ceiling keel should meet the national and industrial standards.

The application of stone aluminum honeycomb panel ceiling reflects the concept of green environmental protection. The stone of the suspended ceiling of the museum is integrated with the dry hanging stone of the interior and exterior walls, which is luxurious and full of the sense of The Times.

Shandong iGolden Furniture Co., Ltd. was established in 2012 in Jinan City, Shandong Province which is one of the biggest professional manufacturers of furniture and board. Such as hospital furniture, bank furniture various customized office furniture,Aluminum honeycomb panel and compact laminate board. iGOLDENOF is a large-scale manufacturing enterprise integrating design, development, production and sales. In past ten years, IGOLDENOF has insisted on open-mindedness, solidarity, mutual assistance, hardworking, pragmatic and humble entrepreneurial spirit and the pursuit of excellence who has been highly recognized and appraised by customers from all over the world.