1: observe the thickness of the substrate and the thickness of the film

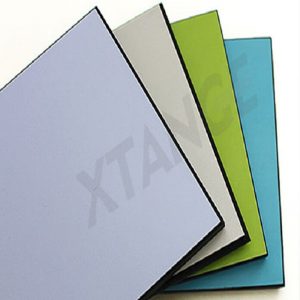

Color steel plate is composed of a substrate and a colored peritoneum or coating. We first have to consider the thickness of the substrate and peritoneum coating, the better color plate substrate is 0.02~0.05mm, film or coating thickness is often only 0.15mm below. Because from the effect of color steel plate use time, the thickness of the substrate is very important. And some manufacturers in the substrate and color plate coating or coating changes, they reduce the thickness of the substrate, but increase the thickness of the peritoneum to reduce the production cost of color plate, which greatly reduces the service life of the color plate.

2: observe the leakage edge of the color steel plate

Get a color steel plate, I first observe the color steel plate exposed steel such as section is fine crystal, whether gray, dark and impurities. If the section is crystalline fine type is superior quality.

3: Listen to the sound

Use your fingers or hard objects to hit the color steel plate. If the color steel plate material is poor, the sound is dull, the metal sound is not obvious, and the color steel plate metal sound is louder and clearer.

4: check the quality certificate of color steel plate

Whether there are inspection standards of relevant departments. If possible, try to go to the manufacturers of color steel plate field visit. See the environment of the enterprise how, whether regular. Market to inquire about the enterprise’s reputation.

5: look at the price

You get what you pay for everything. When we compare the quality of color steel plate, the price is one thing, but do not pay too much attention to the price. If the price of a color steel plate is much lower than the other, then we should pay attention to it.