Application of aluminum honeycomb panel in railway at home and abroad

In foreign countries, TGV series of French high-speed trains and ETR series of Italian high-speed trains have long adopted honeycomb sandwich structure composite material to make interior wall panels and roof. Subsequently, many Railway vehicle manufacturers in Europe have adopted aluminum honeycomb panel to manufacture railway vehicle parts. The application scope covers the side wall panel, inner roof, inner wall panel, floor, inner and outer door panel and luggage rack and other parts in the inner installation structure. Among them, Italy is relatively leading in the application of aluminum honeycomb panels, Italy has long begun to use aluminum honeycomb panels to make complex shape luggage racks and inner wall panels with curved Windows and other structural parts.

In China, the earliest application of aluminum honeycomb panel is to manufacture the compartment wall of 25A soft sleeper bus, but the application effect is not very ideal due to the lack of manufacturing technology at that time. Therefore, it could not be further popularized and applied in the following type 25 buses. At the end of the 20th century, due to the high requirement of vehicle lightweight in the development process of EMU, the aluminum honeycomb panel was firstly used to manufacture the wall, flat top panel and door panel on the domestic EMU sample car, which achieved good results. Subsequently, a large area of the application of aluminum honeycomb panel, then not only used aluminum honeycomb panel to manufacture the partition, flat roof panel, vehicle under equipment cabin bottom plate and a variety of door panels. Also made of aluminum honeycomb panel air-conditioning duct and air conditioning unit dome, which asked to wall, ceiling board, air conditioning duct and air conditioning unit dome application effect of the most significant, greatly reduce the quality of the related parts and components, implement the overall vehicle lightweighting, and improve the precision and quality of parts and components manufacturing, thus improves the manufacturing quality of the vehicle.

However, it is the CRH series emU that really makes breakthrough progress in the application of aluminum honeycomb panel. The breakthrough here is mainly reflected in two aspects:

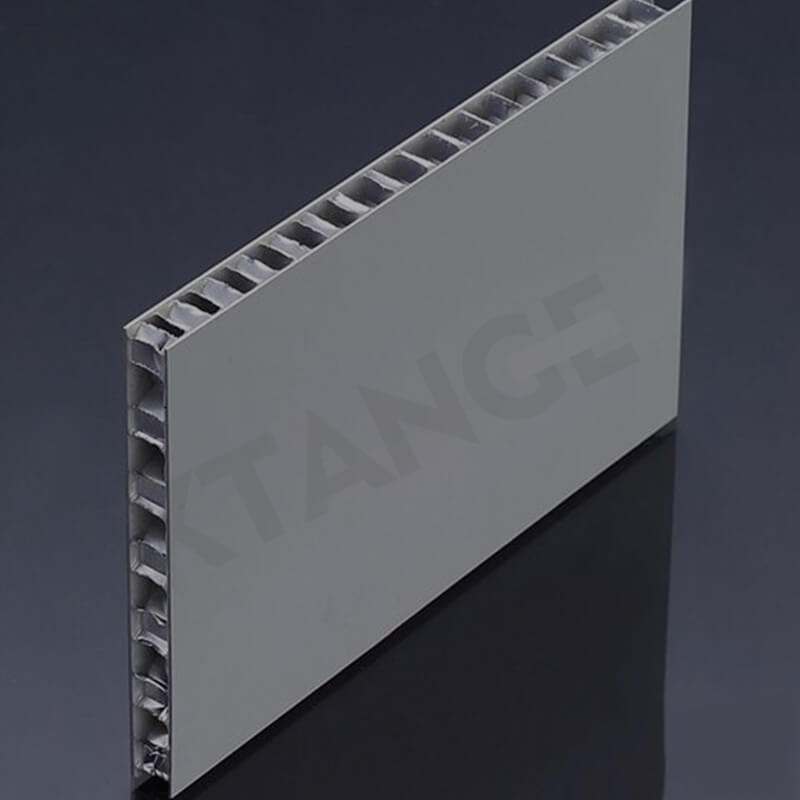

(1) The inner wall panels with complex shapes, high manufacturing tolerances and high appearance quality requirements are made by using aluminum honeycomb panels on CRH series EMUS, breaking through the design concept that aluminum honeycomb panels can only be used to manufacture flat structures or bend in one direction. So that its application scope breaks through the inner floor, the partition wall, all kinds of car inside and outside door panels and air duct of air conditioning system and other application limits.

(2) By applying aluminum honeycomb panels on CRH series EMUS, a luggage rack with complex shape and high load bearing and wear resistance requirements is made, which breaks through the traditional design concept that aluminum honeycomb panels cannot be used in manufacturing important stress components of vehicle internal structure, thus extending its application scope to a new field. The domestic aluminum honeycomb panel application technology into a new stage.

With the continuous deepening of the localization of CRH series EMUS in recent years, China has been able to use aluminum honeycomb panel forming processing technology to manufacture parts with complex shapes, and reached a high level in the field of aluminum honeycomb panel forming manufacturing and application. However, in order to further improve the level of the application of aluminum honeycomb panel and improve the rationality of the design and manufacture of components, maturity and reliability, it should also be the characteristics and applicability, application of aluminum honeycomb panel design method, the manufacture of manufacturability and specific methods and means to further strengthen research, grasp the characteristics and application of aluminum honeycomb panel design method, In order to further expand the application range of aluminum honeycomb panel, promote the further lightweight of railway vehicles.

Shandong iGolden Furniture Co., Ltd. was established in 2012 in Jinan City, Shandong Province which is one of the biggest professional manufacturers of furniture and board. Such as hospital furniture, bank furniture various customized office furniture,Aluminum honeycomb panel and compact laminate board. iGOLDENOF is a large-scale manufacturing enterprise integrating design, development, production and sales. In past ten years, IGOLDENOF has insisted on open-mindedness, solidarity, mutual assistance, hardworking, pragmatic and humble entrepreneurial spirit and the pursuit of excellence who has been highly recognized and appraised by customers from all over the world.