When we choose building materials, we often compare aluminum corrugated board and aluminum honeycomb board together. Why is this? In fact, these two kinds of building materials have many similarities, such as raw materials, but also a lot of differences. Today, professional aluminum honeycomb panel manufacturers will explain the difference between aluminum corrugated panel and aluminum honeycomb panel.

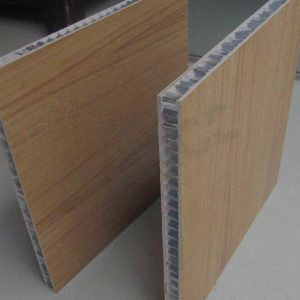

The production process of aluminum honeycomb panel is all carried out in the aluminum honeycomb panel manufacturer and processing plant, and the automatic honeycomb panel composite material production line equipment is compounded according to the pressure and high temperature, which gets rid of the previous toughness problem of honeycomb panel rubber layer. The inner layer is hexagonal honeycomb aluminum, made from aluminum alloy profiles with strength greater than H19. It is attached to the sandwich structure as a joinery board and withstands the upward cutting force. As with many I-beams, this freestanding honeycomb structure can be used to distribute working pressure from the direction of the control panel, thus making the plate support symmetrical and thus ensuring that the control panel remains high flatness over the entire large area. Aluminum corrugated board, also known as corrugated aluminum board, pressed aluminum board, aluminum tile, etc., is suitable for industrial production and industrial buildings, warehouses, special engineering buildings, large span light steel structure flat roof, wall and interior and exterior decoration.